This blog will focus on the measurement of the anti-blooming capabilities of a monochrome sensor. As known, blooming occurs when a (group of) pixel(s) is overexposed and the photodiode can no longer store all generated charges. With an anti-blooming structure inside the pixel, the excessively generated charges can be drained, e.g. excessive electrons can escape through the reset transistor to the power supply. But every anti-blooming structure has its limitations, and with this measurement we try to find the limits of the anti-blooming structure present in a pixel.

What is checked with this measurement is simply the size of an overexposed sensor area. If the illumination level is increased, ideally the size of such an overexposed area should stay constant even with an overexposure. But in reality and while the illumination level is increasing, the size of the overexposed area will grow due to several mechanisms :

- Diffraction at the various edges of the metal lines above a pixel will “guide” photons to neighbouring pixels,

- Multiple reflections in the multi-level layer structure above the pixels can also “guide” photons to neighbouring pixels,

- Fresnel reflections on the sensor surface and on the lens surface can result in ghosting structures,

- Diffraction and reflections at the edges of the iris/diaphragm present in the optical system,

- Optical and electrical cross-talk between the pixels,

- Light piping underneath the metal lines and/or metal shields,

- Blooming effects after the pixels are saturated and the anti-blooming is no capable of handling the excess charges.

All these effects are proportional to the amount of light that comes to the sensor. In the measurements, the amount of light to the sensor is modulated by changing the exposure time. That means that all these effects can be written down with a formula that contains a linear coefficient in relation to the exposure time. This is true for all abovementioned effects, except for the blooming. The blooming also has a linear relationship with exposure time, but with a particular threshold. Below a certain exposure time, the pixel will not be saturated or the anti-blooming capabilities are performing well so that no blooming occurs. Above a certain exposure time, the blooming effect will start and will be added to all other effects that grow the overexposure sensor area. So the measurement will explore the size of an overexposure area as a function of exposure time and will try to find the knee point at which level the blooming effect occurs.

The measurement is performed as follows (to measure the anti-blooming along columns in vertical direction) :

- The sensor is illuminated with a target that allows a black-white transition about half-way the sensor height, and the black-white transition horizontally crosses a column in the middle of the sensor (e.g. column 380 out of 752 active columns)

- The location of the black-white transition is monitored in the images generated by the sensor. To do so, the balck-white transition is defined at a level of 75 % of the white part of the test target (75 % is randomly chosen, any other value can do the job as well),

- The illumination of the target is kept constant (white fluorescent DC light), and to get different light levels on the sensor, the exposure time of the imager is changed from very small values to very large values,

- While changing the exposure levels, the location black-white transition is constantly calculated to monitor the growth of the overexposed area.

Figure 1 shows one of the images captured at the onset of saturation, Figure 2 illustrates the situation at 10 times overexposure, Figure 3 is the result while overexposing the sensor 100 times, and finally Figure 4 illustrates a factor of 1000 times overexposure.

Figure 1 : Image of the test target at the moment the sensor starts to saturate [0015].

Figure 2 : Image of the test target at the moment the sensor is 10 times overexposed [0019].

Figure 3 : Image of the test target at the moment the sensor is 100 times overexposed [0029].

Figure 4 : Image of the test target at the moment the sensor is 1000 times overexposed [0039].

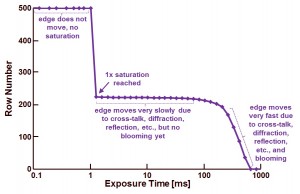

A simple software tool is developed to check for every exposure time, on which row the horizontal black-white crossing is occurring in the images. If the pixels are not saturated yet, the software tool simply outputs row number “500”, which actually does not exist. As soon as at a particular illumination level the pixels in the white region reach 75 % of saturation, the measurement tool outputs the row number at which the black-white transition occurs. If the overexposed area reaches the top of the image, like shown in Figure 4, the output of the measurement tool is equal to “0”. The result of this analysis is shown in Figure 5.

Figure 5 : Position of the black-white transition (indicated as row number) as a function of exposure time.

In Figure 5, from left to right, the following information is available :

- For small exposure times (< 1 ms), the white pixels are not yet reaching 75 % of saturation, this is indicated by the row value equal to “500”,

- For an exposure value of 1.28 ms, saturation occurs (= 75 %) and the black-white transition is located at row number “224”,

- From this moment onwards the large white area starts growing slowly due to all kind of optical artefacts, listed already earlier in this blog,

- For exposure times larger than 200 ms, the area of the white spot grows very fast, as can be seen in the graph. This change in “speed” is due to the blooming artefact that apparently occurs at very high exposure levels.

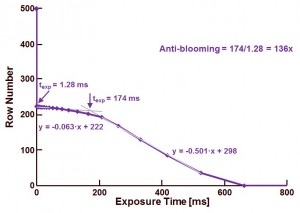

To calculate a number for the anti-blooming capabilities of the sensor, the same data as present in Figure 5 is shown again on a linear scale as illustrated in Figure 6.

Figure 6 : The same information is shown as already illustrated in Figure 5, but now on a linear scale.

The two important regions (saturated but no blooming and saturated with blooming) are approximated by means of a linear regression line. And as can be seen, below 174 ms exposure time, blooming plays no important role, but above 174 ms exposure time, blooming is dominating over all other artefacts. The exposure time of 174 ms seems to be a cross-over exposure time.

The anti-blooming capability is then defined as the ratio of the exposure time at which saturation is reached (texp = 1.28 ms) and the cross-over exposure time (texp = 174 ms), resulting in an anti-blooming capability of 136 times overexposure.

In conclusion : a long story to explain a relative simple measurement. More anti-blooming stuff to follow.

Albert, 28-08-2015.

![// Captured 10:10:01 - Tuesday, August 25, 2015//// Frame 1 of 10 frames// Sensor info:// Width = 752// Height = 480// Image Format = Bayer 10// Subformat = BGGR// Sensor output = 10 bits per pixel//// .TIF file (RGB 48Bpp)//// Application version info:// Application name = DevWare.exe// Application version = 3.1.0.21// Application type = 3.1-Beta8// Application date = 12/04/2009// Firmware version = D.28//// Camera info:// productID = 0x100D Version = 0xC1// productName = Aptina Imaging DEMO2X// transportName = USB 2.0// num_chips = 1// sensor->sensorName = MI-0351// sensor->versionName = REV4// sensor->sensorFileName = sensor_dataMT9V024-REV4.sdat//// Sensor Fuse info:// FuseID: 308F9B95DFB5246B// Revision: 4// Silicon Option: --// // Windows OS info:// Display resolution = 1440x900 at 32bpp// OS Versioninfo = (5, 1, 2600, 2, Service Pack 2, 2, 0)// Microsoft Windows XP // Service Pack 2//// Processor info:// 1828 MHz// GenuineIntel// Intel(R) Core(TM)2 CPU T5600 @ 1.83GHz// 38 percent of memory is in use.// Memory 1014 MB (total)// Memory 625 MB (available)// Intel Pentium III//// USB 2.0 Enhanced Host Controllers:// Service: usbehci// Driver File: C:WINDOWSsystem32DRIVERSusbehci.sys// File Version: 5.1.2600.2180// Device Desc: Standard Enhanced PCI to USB Host Controller//// Aptina Imaging Camera Driver Info:// Service: MIUSB2// Driver File: C:WINDOWSSystem32Driversmiusb2.sys// File Version: 5.1.0.3508// Found Device: Vid_0634&Pid_100d// Service CYUSB not found// Service CYUSB not found[ColorPipe State]STATE= Display Zoom, 13STATE= Display Zoom Percent, 100STATE= Master Clock, 13500897STATE= Update Sensor FPS, 0STATE= Allow Update Sensor FPS, 1STATE= BitDepth, 10STATE= Filter, 3STATE= X Offset, 0STATE= Y Offset, 1STATE= Auto Offset, 1STATE= CFA Pattern, 0STATE= RGBC BiWindow, 2STATE= Monochrome, 1STATE= True Black Enable, 0STATE= True Black Level, 42STATE= Auto Luma Range, 1STATE= Luma Lo, 0STATE= Luma Hi, 255STATE= Unswizzle Mode, 3STATE= Swap 12-bit LSBs, 0STATE= Deinterlace Mode, 3STATE= Output Channel, 0STATE= Output BwColor, 0STATE= sRGB Color Standard, 0STATE= Color Correction, 0STATE= Gamma, 9STATE= Black Correct, 5STATE= Saturation, 10STATE= Contrast, 25STATE= Aperture Enable, 0STATE= Aperture, 5STATE= Black CCM Kill Enable, 0STATE= Black CCM Kill A, 240STATE= Black CCM Kill B, 160STATE= Black CCM Kill C, 80STATE= Green Balance Enable, 0STATE= Green Balance Apos, 128STATE= Green Balance Bpos, 10STATE= Green Balance Aneg, -128STATE= Green Balance Bneg, 10STATE= Auto Exposure, 0STATE= Auto Exposure Target, 50STATE= Auto Exposure Stability, 6STATE= Auto Exposure Speed, 30STATE= Auto Exposure Minimum FPS, 5STATE= Auto Exposure Flicker Filter, 0STATE= Auto Exposure Soft Limit, 33STATE= Auto Exposure Soft Gain Limit, 40STATE= Auto Exposure Software Gain Limit, 100STATE= Auto Exposure Freeze Gains, 0STATE= Auto Exposure Fade Saturation, 1STATE= Auto Exposure Fade Aperture, 1STATE= Auto Exposure Fade Target, 1STATE= Auto Exposure Inner Zone, 50STATE= Auto Exposure Outer Zone, 50STATE= Software Gain, 1000STATE= Mechanical Shutter Same, 1STATE= Mechanical Shutter Time, 33333STATE= Mechanical Shutter Delay, 0STATE= White Balance, 3STATE= WB Speed, 15STATE= WB Adjust Gains, 0STATE= WB Manual Position, 40STATE= WB Manual RedGreen, 100STATE= WB Manual BlueGreen, 100STATE= WB Interpolate Saturation, 1STATE= WB Normalize Matrix, 1STATE= AWB Weight Map Method, 0STATE= AWB Weight Map X Scale, 0STATE= AWB Weight Map Y Scale, 0STATE= AWB Weight Map X Shift, 0STATE= AWB Weight Map Y Shift, 0STATE= AWB Weight Map X Center, 0STATE= AWB Weight Map Y Center, 0STATE= AWB Weight Map Angle Sin, 0STATE= AWB Weight Map Angle Cos, 0STATE= AWB Weight Map Luma Low, 0STATE= AWB Weight Map Luma High, 0STATE= Minimum Gain, 1000STATE= Show Min Gain As 1, 1STATE= Default Relative Red Gain, 1000STATE= Default Relative Blue Gain, 1000STATE= Relative Red Gain, 1000STATE= Relative Blue Gain, 1000STATE= Lens Correction Enable, 0STATE= Lens Correction Falloff, 100STATE= Lens Correction Overlay, 0STATE= Lens Correction Center X, 376STATE= Lens Correction Center Y, 240STATE= Lens Correction Coeff Prec, 16STATE= Lens Correction Wide Angle, 0STATE= Lens Center Red X, 376STATE= Lens Center Red Y, 240STATE= Lens Center Green1 X, 376STATE= Lens Center Green1 Y, 240STATE= Lens Center Green2 X, 376STATE= Lens Center Green2 Y, 240STATE= Lens Center Blue X, 376STATE= Lens Center Blue Y, 240STATE= Lens Center Overlay, 0STATE= Lens Sim Sensor, 0STATE= Lens Sim Sensor Rev, 0STATE= Lens Sim Enable Pwq, 0STATE= Lens Sim Enable Poly, 0STATE= Noise Removal, 0STATE= Noise Removal Level, 25STATE= Noise Removal K1, 2000STATE= Noise Removal K2, 1800STATE= Noise Removal K3, 1000STATE= Noise Removal Edges, 1STATE= Noise Removal Kernel, 0STATE= HiDy 14bits, 0STATE= HiDy NR Enable, 0STATE= HiDy PreWB Autogain, 1STATE= HiDy TM Apply S-Curve, 1STATE= HiDy TM Enable LTM, 1STATE= Defect Enable, 0STATE= Defect Max, 1000STATE= Defect Auto Defect Correction, 0STATE= Flash Lamp, 0STATE= Still Global Reset, 0STATE= Global Reset Bulb, 0STATE= Num Capture Frames, 10STATE= Still Mode, 1STATE= Still Capture Average, 0STATE= Still Capture Timeout, 5STATE= Delay before snap, 0STATE= Save 24bpp BMP, 0STATE= Save RAW, 0STATE= Save TXT, 0STATE= Save HEX, 0STATE= Save ITX, 0STATE= Save RAW TIFF, 0STATE= Save 48bpp COLOR TIFF, 1STATE= Save JPEG, 0STATE= Save RAW JPEG, 0STATE= Save BMP Info, 0STATE= JPEG Quality (1-100), 100STATE= Save RAW PNG, 0STATE= Save PNG, 0STATE= Save DNG, 0STATE= Save Selection Rectangle, 0STATE= ICC Profile, 0STATE= Video Screen Capture, 1STATE= RAM Capture, 0STATE= RAM Capture MB, 512STATE= RAM Capture Cycle, 1STATE= WB Xenon Red Gain, 1024STATE= WB Xenon Blue Gain, 1024STATE= WB Led Red Gain, 1024STATE= WB Led Blue Gain, 1024STATE= MAE Overlay, 0STATE= Noise Image Type, 0STATE= Noise Frames, 50STATE= Strip FSP, 1STATE= Thumbnail Overlay, 1STATE= Check Thumbnail Table, 0STATE= CRA Overlay, 0STATE= Allow FAR Access, 1STATE= Pure Raw, 0STATE= AWB Incandescent, 1.3 -0.11 -0.18 -0.47 2.03 -0.49 -0.86 -0.79 5.66STATE= AWB Sun, 2.13 -0.09 -0.15 -0.44 2.09 -0.5 -0.1 -0.31 1.97STATE= AWB Incandescent Gain, 1 1STATE= AWB Sun Gain, 1 1STATE= WB Custom, 1 0 0 0 1 0 0 0 1STATE= WB Custom Xenon, 1 0 0 0 1 0 0 0 1STATE= WB Custom Led, 1 0 0 0 1 0 0 0 1STATE= AWB Weight Map, 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0STATE= Lens Curve Red, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green1, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green2, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Blue, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= RGBC Sigma_S, 1STATE= RGBC Sigma_I, 0.005STATE= RGBC Smooth_Th, 0.1STATE= HiDy Matrix, 1.6475 -0.7464 0.0989 -0.0636 1.0086 0.055 -0.0266 -0.8366 1.8632STATE= HiDy NR Noise Model Coef, 1STATE= HiDy PreWB Gb, 1STATE= HiDy PreWB Gr, 1STATE= HiDy TM Peak Percent, 0.003STATE= HiDy TM Sharp S, 2STATE= Gain Table, (null)](http://harvestimaging.com/blog/wp-content/uploads/2015/08/next_blog_11-300x191.jpg)

![// Captured 10:11:22 - Tuesday, August 25, 2015//// Frame 1 of 10 frames// Sensor info:// Width = 752// Height = 480// Image Format = Bayer 10// Subformat = BGGR// Sensor output = 10 bits per pixel//// .TIF file (RGB 48Bpp)//// Application version info:// Application name = DevWare.exe// Application version = 3.1.0.21// Application type = 3.1-Beta8// Application date = 12/04/2009// Firmware version = D.28//// Camera info:// productID = 0x100D Version = 0xC1// productName = Aptina Imaging DEMO2X// transportName = USB 2.0// num_chips = 1// sensor->sensorName = MI-0351// sensor->versionName = REV4// sensor->sensorFileName = sensor_dataMT9V024-REV4.sdat//// Sensor Fuse info:// FuseID: 308F9B95DFB5246B// Revision: 4// Silicon Option: --// // Windows OS info:// Display resolution = 1440x900 at 32bpp// OS Versioninfo = (5, 1, 2600, 2, Service Pack 2, 2, 0)// Microsoft Windows XP // Service Pack 2//// Processor info:// 1828 MHz// GenuineIntel// Intel(R) Core(TM)2 CPU T5600 @ 1.83GHz// 38 percent of memory is in use.// Memory 1014 MB (total)// Memory 619 MB (available)// Intel Pentium III//// USB 2.0 Enhanced Host Controllers:// Service: usbehci// Driver File: C:WINDOWSsystem32DRIVERSusbehci.sys// File Version: 5.1.2600.2180// Device Desc: Standard Enhanced PCI to USB Host Controller//// Aptina Imaging Camera Driver Info:// Service: MIUSB2// Driver File: C:WINDOWSSystem32Driversmiusb2.sys// File Version: 5.1.0.3508// Found Device: Vid_0634&Pid_100d// Service CYUSB not found// Service CYUSB not found[ColorPipe State]STATE= Display Zoom, 13STATE= Display Zoom Percent, 100STATE= Master Clock, 13500897STATE= Update Sensor FPS, 0STATE= Allow Update Sensor FPS, 1STATE= BitDepth, 10STATE= Filter, 3STATE= X Offset, 0STATE= Y Offset, 1STATE= Auto Offset, 1STATE= CFA Pattern, 0STATE= RGBC BiWindow, 2STATE= Monochrome, 1STATE= True Black Enable, 0STATE= True Black Level, 42STATE= Auto Luma Range, 1STATE= Luma Lo, 0STATE= Luma Hi, 255STATE= Unswizzle Mode, 3STATE= Swap 12-bit LSBs, 0STATE= Deinterlace Mode, 3STATE= Output Channel, 0STATE= Output BwColor, 0STATE= sRGB Color Standard, 0STATE= Color Correction, 0STATE= Gamma, 9STATE= Black Correct, 5STATE= Saturation, 10STATE= Contrast, 25STATE= Aperture Enable, 0STATE= Aperture, 5STATE= Black CCM Kill Enable, 0STATE= Black CCM Kill A, 240STATE= Black CCM Kill B, 160STATE= Black CCM Kill C, 80STATE= Green Balance Enable, 0STATE= Green Balance Apos, 128STATE= Green Balance Bpos, 10STATE= Green Balance Aneg, -128STATE= Green Balance Bneg, 10STATE= Auto Exposure, 0STATE= Auto Exposure Target, 50STATE= Auto Exposure Stability, 6STATE= Auto Exposure Speed, 30STATE= Auto Exposure Minimum FPS, 5STATE= Auto Exposure Flicker Filter, 0STATE= Auto Exposure Soft Limit, 33STATE= Auto Exposure Soft Gain Limit, 40STATE= Auto Exposure Software Gain Limit, 100STATE= Auto Exposure Freeze Gains, 0STATE= Auto Exposure Fade Saturation, 1STATE= Auto Exposure Fade Aperture, 1STATE= Auto Exposure Fade Target, 1STATE= Auto Exposure Inner Zone, 50STATE= Auto Exposure Outer Zone, 50STATE= Software Gain, 1000STATE= Mechanical Shutter Same, 1STATE= Mechanical Shutter Time, 33333STATE= Mechanical Shutter Delay, 0STATE= White Balance, 3STATE= WB Speed, 15STATE= WB Adjust Gains, 0STATE= WB Manual Position, 40STATE= WB Manual RedGreen, 100STATE= WB Manual BlueGreen, 100STATE= WB Interpolate Saturation, 1STATE= WB Normalize Matrix, 1STATE= AWB Weight Map Method, 0STATE= AWB Weight Map X Scale, 0STATE= AWB Weight Map Y Scale, 0STATE= AWB Weight Map X Shift, 0STATE= AWB Weight Map Y Shift, 0STATE= AWB Weight Map X Center, 0STATE= AWB Weight Map Y Center, 0STATE= AWB Weight Map Angle Sin, 0STATE= AWB Weight Map Angle Cos, 0STATE= AWB Weight Map Luma Low, 0STATE= AWB Weight Map Luma High, 0STATE= Minimum Gain, 1000STATE= Show Min Gain As 1, 1STATE= Default Relative Red Gain, 1000STATE= Default Relative Blue Gain, 1000STATE= Relative Red Gain, 1000STATE= Relative Blue Gain, 1000STATE= Lens Correction Enable, 0STATE= Lens Correction Falloff, 100STATE= Lens Correction Overlay, 0STATE= Lens Correction Center X, 376STATE= Lens Correction Center Y, 240STATE= Lens Correction Coeff Prec, 16STATE= Lens Correction Wide Angle, 0STATE= Lens Center Red X, 376STATE= Lens Center Red Y, 240STATE= Lens Center Green1 X, 376STATE= Lens Center Green1 Y, 240STATE= Lens Center Green2 X, 376STATE= Lens Center Green2 Y, 240STATE= Lens Center Blue X, 376STATE= Lens Center Blue Y, 240STATE= Lens Center Overlay, 0STATE= Lens Sim Sensor, 0STATE= Lens Sim Sensor Rev, 0STATE= Lens Sim Enable Pwq, 0STATE= Lens Sim Enable Poly, 0STATE= Noise Removal, 0STATE= Noise Removal Level, 25STATE= Noise Removal K1, 2000STATE= Noise Removal K2, 1800STATE= Noise Removal K3, 1000STATE= Noise Removal Edges, 1STATE= Noise Removal Kernel, 0STATE= HiDy 14bits, 0STATE= HiDy NR Enable, 0STATE= HiDy PreWB Autogain, 1STATE= HiDy TM Apply S-Curve, 1STATE= HiDy TM Enable LTM, 1STATE= Defect Enable, 0STATE= Defect Max, 1000STATE= Defect Auto Defect Correction, 0STATE= Flash Lamp, 0STATE= Still Global Reset, 0STATE= Global Reset Bulb, 0STATE= Num Capture Frames, 10STATE= Still Mode, 1STATE= Still Capture Average, 0STATE= Still Capture Timeout, 5STATE= Delay before snap, 0STATE= Save 24bpp BMP, 0STATE= Save RAW, 0STATE= Save TXT, 0STATE= Save HEX, 0STATE= Save ITX, 0STATE= Save RAW TIFF, 0STATE= Save 48bpp COLOR TIFF, 1STATE= Save JPEG, 0STATE= Save RAW JPEG, 0STATE= Save BMP Info, 0STATE= JPEG Quality (1-100), 100STATE= Save RAW PNG, 0STATE= Save PNG, 0STATE= Save DNG, 0STATE= Save Selection Rectangle, 0STATE= ICC Profile, 0STATE= Video Screen Capture, 1STATE= RAM Capture, 0STATE= RAM Capture MB, 512STATE= RAM Capture Cycle, 1STATE= WB Xenon Red Gain, 1024STATE= WB Xenon Blue Gain, 1024STATE= WB Led Red Gain, 1024STATE= WB Led Blue Gain, 1024STATE= MAE Overlay, 0STATE= Noise Image Type, 0STATE= Noise Frames, 50STATE= Strip FSP, 1STATE= Thumbnail Overlay, 1STATE= Check Thumbnail Table, 0STATE= CRA Overlay, 0STATE= Allow FAR Access, 1STATE= Pure Raw, 0STATE= AWB Incandescent, 1.3 -0.11 -0.18 -0.47 2.03 -0.49 -0.86 -0.79 5.66STATE= AWB Sun, 2.13 -0.09 -0.15 -0.44 2.09 -0.5 -0.1 -0.31 1.97STATE= AWB Incandescent Gain, 1 1STATE= AWB Sun Gain, 1 1STATE= WB Custom, 1 0 0 0 1 0 0 0 1STATE= WB Custom Xenon, 1 0 0 0 1 0 0 0 1STATE= WB Custom Led, 1 0 0 0 1 0 0 0 1STATE= AWB Weight Map, 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0STATE= Lens Curve Red, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green1, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green2, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Blue, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= RGBC Sigma_S, 1STATE= RGBC Sigma_I, 0.005STATE= RGBC Smooth_Th, 0.1STATE= HiDy Matrix, 1.6475 -0.7464 0.0989 -0.0636 1.0086 0.055 -0.0266 -0.8366 1.8632STATE= HiDy NR Noise Model Coef, 1STATE= HiDy PreWB Gb, 1STATE= HiDy PreWB Gr, 1STATE= HiDy TM Peak Percent, 0.003STATE= HiDy TM Sharp S, 2STATE= Gain Table, (null)](http://harvestimaging.com/blog/wp-content/uploads/2015/08/next_blog_21-300x191.jpg)

![// Captured 10:15:02 - Tuesday, August 25, 2015//// Frame 1 of 10 frames// Sensor info:// Width = 752// Height = 480// Image Format = Bayer 10// Subformat = BGGR// Sensor output = 10 bits per pixel//// .TIF file (RGB 48Bpp)//// Application version info:// Application name = DevWare.exe// Application version = 3.1.0.21// Application type = 3.1-Beta8// Application date = 12/04/2009// Firmware version = D.28//// Camera info:// productID = 0x100D Version = 0xC1// productName = Aptina Imaging DEMO2X// transportName = USB 2.0// num_chips = 1// sensor->sensorName = MI-0351// sensor->versionName = REV4// sensor->sensorFileName = sensor_dataMT9V024-REV4.sdat//// Sensor Fuse info:// FuseID: 308F9B95DFB5246B// Revision: 4// Silicon Option: --// // Windows OS info:// Display resolution = 1440x900 at 32bpp// OS Versioninfo = (5, 1, 2600, 2, Service Pack 2, 2, 0)// Microsoft Windows XP // Service Pack 2//// Processor info:// 1828 MHz// GenuineIntel// Intel(R) Core(TM)2 CPU T5600 @ 1.83GHz// 39 percent of memory is in use.// Memory 1014 MB (total)// Memory 608 MB (available)// Intel Pentium III//// USB 2.0 Enhanced Host Controllers:// Service: usbehci// Driver File: C:WINDOWSsystem32DRIVERSusbehci.sys// File Version: 5.1.2600.2180// Device Desc: Standard Enhanced PCI to USB Host Controller//// Aptina Imaging Camera Driver Info:// Service: MIUSB2// Driver File: C:WINDOWSSystem32Driversmiusb2.sys// File Version: 5.1.0.3508// Found Device: Vid_0634&Pid_100d// Service CYUSB not found// Service CYUSB not found[ColorPipe State]STATE= Display Zoom, 13STATE= Display Zoom Percent, 100STATE= Master Clock, 13500897STATE= Update Sensor FPS, 0STATE= Allow Update Sensor FPS, 1STATE= BitDepth, 10STATE= Filter, 3STATE= X Offset, 0STATE= Y Offset, 1STATE= Auto Offset, 1STATE= CFA Pattern, 0STATE= RGBC BiWindow, 2STATE= Monochrome, 1STATE= True Black Enable, 0STATE= True Black Level, 42STATE= Auto Luma Range, 1STATE= Luma Lo, 0STATE= Luma Hi, 255STATE= Unswizzle Mode, 3STATE= Swap 12-bit LSBs, 0STATE= Deinterlace Mode, 3STATE= Output Channel, 0STATE= Output BwColor, 0STATE= sRGB Color Standard, 0STATE= Color Correction, 0STATE= Gamma, 9STATE= Black Correct, 5STATE= Saturation, 10STATE= Contrast, 25STATE= Aperture Enable, 0STATE= Aperture, 5STATE= Black CCM Kill Enable, 0STATE= Black CCM Kill A, 240STATE= Black CCM Kill B, 160STATE= Black CCM Kill C, 80STATE= Green Balance Enable, 0STATE= Green Balance Apos, 128STATE= Green Balance Bpos, 10STATE= Green Balance Aneg, -128STATE= Green Balance Bneg, 10STATE= Auto Exposure, 0STATE= Auto Exposure Target, 50STATE= Auto Exposure Stability, 6STATE= Auto Exposure Speed, 30STATE= Auto Exposure Minimum FPS, 5STATE= Auto Exposure Flicker Filter, 0STATE= Auto Exposure Soft Limit, 33STATE= Auto Exposure Soft Gain Limit, 40STATE= Auto Exposure Software Gain Limit, 100STATE= Auto Exposure Freeze Gains, 0STATE= Auto Exposure Fade Saturation, 1STATE= Auto Exposure Fade Aperture, 1STATE= Auto Exposure Fade Target, 1STATE= Auto Exposure Inner Zone, 50STATE= Auto Exposure Outer Zone, 50STATE= Software Gain, 1000STATE= Mechanical Shutter Same, 1STATE= Mechanical Shutter Time, 33333STATE= Mechanical Shutter Delay, 0STATE= White Balance, 3STATE= WB Speed, 15STATE= WB Adjust Gains, 0STATE= WB Manual Position, 40STATE= WB Manual RedGreen, 100STATE= WB Manual BlueGreen, 100STATE= WB Interpolate Saturation, 1STATE= WB Normalize Matrix, 1STATE= AWB Weight Map Method, 0STATE= AWB Weight Map X Scale, 0STATE= AWB Weight Map Y Scale, 0STATE= AWB Weight Map X Shift, 0STATE= AWB Weight Map Y Shift, 0STATE= AWB Weight Map X Center, 0STATE= AWB Weight Map Y Center, 0STATE= AWB Weight Map Angle Sin, 0STATE= AWB Weight Map Angle Cos, 0STATE= AWB Weight Map Luma Low, 0STATE= AWB Weight Map Luma High, 0STATE= Minimum Gain, 1000STATE= Show Min Gain As 1, 1STATE= Default Relative Red Gain, 1000STATE= Default Relative Blue Gain, 1000STATE= Relative Red Gain, 1000STATE= Relative Blue Gain, 1000STATE= Lens Correction Enable, 0STATE= Lens Correction Falloff, 100STATE= Lens Correction Overlay, 0STATE= Lens Correction Center X, 376STATE= Lens Correction Center Y, 240STATE= Lens Correction Coeff Prec, 16STATE= Lens Correction Wide Angle, 0STATE= Lens Center Red X, 376STATE= Lens Center Red Y, 240STATE= Lens Center Green1 X, 376STATE= Lens Center Green1 Y, 240STATE= Lens Center Green2 X, 376STATE= Lens Center Green2 Y, 240STATE= Lens Center Blue X, 376STATE= Lens Center Blue Y, 240STATE= Lens Center Overlay, 0STATE= Lens Sim Sensor, 0STATE= Lens Sim Sensor Rev, 0STATE= Lens Sim Enable Pwq, 0STATE= Lens Sim Enable Poly, 0STATE= Noise Removal, 0STATE= Noise Removal Level, 25STATE= Noise Removal K1, 2000STATE= Noise Removal K2, 1800STATE= Noise Removal K3, 1000STATE= Noise Removal Edges, 1STATE= Noise Removal Kernel, 0STATE= HiDy 14bits, 0STATE= HiDy NR Enable, 0STATE= HiDy PreWB Autogain, 1STATE= HiDy TM Apply S-Curve, 1STATE= HiDy TM Enable LTM, 1STATE= Defect Enable, 0STATE= Defect Max, 1000STATE= Defect Auto Defect Correction, 0STATE= Flash Lamp, 0STATE= Still Global Reset, 0STATE= Global Reset Bulb, 0STATE= Num Capture Frames, 10STATE= Still Mode, 1STATE= Still Capture Average, 0STATE= Still Capture Timeout, 5STATE= Delay before snap, 0STATE= Save 24bpp BMP, 0STATE= Save RAW, 0STATE= Save TXT, 0STATE= Save HEX, 0STATE= Save ITX, 0STATE= Save RAW TIFF, 0STATE= Save 48bpp COLOR TIFF, 1STATE= Save JPEG, 0STATE= Save RAW JPEG, 0STATE= Save BMP Info, 0STATE= JPEG Quality (1-100), 100STATE= Save RAW PNG, 0STATE= Save PNG, 0STATE= Save DNG, 0STATE= Save Selection Rectangle, 0STATE= ICC Profile, 0STATE= Video Screen Capture, 1STATE= RAM Capture, 0STATE= RAM Capture MB, 512STATE= RAM Capture Cycle, 1STATE= WB Xenon Red Gain, 1024STATE= WB Xenon Blue Gain, 1024STATE= WB Led Red Gain, 1024STATE= WB Led Blue Gain, 1024STATE= MAE Overlay, 0STATE= Noise Image Type, 0STATE= Noise Frames, 50STATE= Strip FSP, 1STATE= Thumbnail Overlay, 1STATE= Check Thumbnail Table, 0STATE= CRA Overlay, 0STATE= Allow FAR Access, 1STATE= Pure Raw, 0STATE= AWB Incandescent, 1.3 -0.11 -0.18 -0.47 2.03 -0.49 -0.86 -0.79 5.66STATE= AWB Sun, 2.13 -0.09 -0.15 -0.44 2.09 -0.5 -0.1 -0.31 1.97STATE= AWB Incandescent Gain, 1 1STATE= AWB Sun Gain, 1 1STATE= WB Custom, 1 0 0 0 1 0 0 0 1STATE= WB Custom Xenon, 1 0 0 0 1 0 0 0 1STATE= WB Custom Led, 1 0 0 0 1 0 0 0 1STATE= AWB Weight Map, 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0STATE= Lens Curve Red, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green1, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green2, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Blue, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= RGBC Sigma_S, 1STATE= RGBC Sigma_I, 0.005STATE= RGBC Smooth_Th, 0.1STATE= HiDy Matrix, 1.6475 -0.7464 0.0989 -0.0636 1.0086 0.055 -0.0266 -0.8366 1.8632STATE= HiDy NR Noise Model Coef, 1STATE= HiDy PreWB Gb, 1STATE= HiDy PreWB Gr, 1STATE= HiDy TM Peak Percent, 0.003STATE= HiDy TM Sharp S, 2STATE= Gain Table, (null)](http://harvestimaging.com/blog/wp-content/uploads/2015/08/next_blog_31-300x191.jpg)

![// Captured 10:20:13 - Tuesday, August 25, 2015//// Frame 1 of 10 frames// Sensor info:// Width = 752// Height = 480// Image Format = Bayer 10// Subformat = BGGR// Sensor output = 10 bits per pixel//// .TIF file (RGB 48Bpp)//// Application version info:// Application name = DevWare.exe// Application version = 3.1.0.21// Application type = 3.1-Beta8// Application date = 12/04/2009// Firmware version = D.28//// Camera info:// productID = 0x100D Version = 0xC1// productName = Aptina Imaging DEMO2X// transportName = USB 2.0// num_chips = 1// sensor->sensorName = MI-0351// sensor->versionName = REV4// sensor->sensorFileName = sensor_dataMT9V024-REV4.sdat//// Sensor Fuse info:// FuseID: 308F9B95DFB5246B// Revision: 4// Silicon Option: --// // Windows OS info:// Display resolution = 1440x900 at 32bpp// OS Versioninfo = (5, 1, 2600, 2, Service Pack 2, 2, 0)// Microsoft Windows XP // Service Pack 2//// Processor info:// 1828 MHz// GenuineIntel// Intel(R) Core(TM)2 CPU T5600 @ 1.83GHz// 39 percent of memory is in use.// Memory 1014 MB (total)// Memory 608 MB (available)// Intel Pentium III//// USB 2.0 Enhanced Host Controllers:// Service: usbehci// Driver File: C:WINDOWSsystem32DRIVERSusbehci.sys// File Version: 5.1.2600.2180// Device Desc: Standard Enhanced PCI to USB Host Controller//// Aptina Imaging Camera Driver Info:// Service: MIUSB2// Driver File: C:WINDOWSSystem32Driversmiusb2.sys// File Version: 5.1.0.3508// Found Device: Vid_0634&Pid_100d// Service CYUSB not found// Service CYUSB not found[ColorPipe State]STATE= Display Zoom, 13STATE= Display Zoom Percent, 100STATE= Master Clock, 13500897STATE= Update Sensor FPS, 0STATE= Allow Update Sensor FPS, 1STATE= BitDepth, 10STATE= Filter, 3STATE= X Offset, 0STATE= Y Offset, 1STATE= Auto Offset, 1STATE= CFA Pattern, 0STATE= RGBC BiWindow, 2STATE= Monochrome, 1STATE= True Black Enable, 0STATE= True Black Level, 42STATE= Auto Luma Range, 1STATE= Luma Lo, 0STATE= Luma Hi, 255STATE= Unswizzle Mode, 3STATE= Swap 12-bit LSBs, 0STATE= Deinterlace Mode, 3STATE= Output Channel, 0STATE= Output BwColor, 0STATE= sRGB Color Standard, 0STATE= Color Correction, 0STATE= Gamma, 9STATE= Black Correct, 5STATE= Saturation, 10STATE= Contrast, 25STATE= Aperture Enable, 0STATE= Aperture, 5STATE= Black CCM Kill Enable, 0STATE= Black CCM Kill A, 240STATE= Black CCM Kill B, 160STATE= Black CCM Kill C, 80STATE= Green Balance Enable, 0STATE= Green Balance Apos, 128STATE= Green Balance Bpos, 10STATE= Green Balance Aneg, -128STATE= Green Balance Bneg, 10STATE= Auto Exposure, 0STATE= Auto Exposure Target, 50STATE= Auto Exposure Stability, 6STATE= Auto Exposure Speed, 30STATE= Auto Exposure Minimum FPS, 5STATE= Auto Exposure Flicker Filter, 0STATE= Auto Exposure Soft Limit, 33STATE= Auto Exposure Soft Gain Limit, 40STATE= Auto Exposure Software Gain Limit, 100STATE= Auto Exposure Freeze Gains, 0STATE= Auto Exposure Fade Saturation, 1STATE= Auto Exposure Fade Aperture, 1STATE= Auto Exposure Fade Target, 1STATE= Auto Exposure Inner Zone, 50STATE= Auto Exposure Outer Zone, 50STATE= Software Gain, 1000STATE= Mechanical Shutter Same, 1STATE= Mechanical Shutter Time, 33333STATE= Mechanical Shutter Delay, 0STATE= White Balance, 3STATE= WB Speed, 15STATE= WB Adjust Gains, 0STATE= WB Manual Position, 40STATE= WB Manual RedGreen, 100STATE= WB Manual BlueGreen, 100STATE= WB Interpolate Saturation, 1STATE= WB Normalize Matrix, 1STATE= AWB Weight Map Method, 0STATE= AWB Weight Map X Scale, 0STATE= AWB Weight Map Y Scale, 0STATE= AWB Weight Map X Shift, 0STATE= AWB Weight Map Y Shift, 0STATE= AWB Weight Map X Center, 0STATE= AWB Weight Map Y Center, 0STATE= AWB Weight Map Angle Sin, 0STATE= AWB Weight Map Angle Cos, 0STATE= AWB Weight Map Luma Low, 0STATE= AWB Weight Map Luma High, 0STATE= Minimum Gain, 1000STATE= Show Min Gain As 1, 1STATE= Default Relative Red Gain, 1000STATE= Default Relative Blue Gain, 1000STATE= Relative Red Gain, 1000STATE= Relative Blue Gain, 1000STATE= Lens Correction Enable, 0STATE= Lens Correction Falloff, 100STATE= Lens Correction Overlay, 0STATE= Lens Correction Center X, 376STATE= Lens Correction Center Y, 240STATE= Lens Correction Coeff Prec, 16STATE= Lens Correction Wide Angle, 0STATE= Lens Center Red X, 376STATE= Lens Center Red Y, 240STATE= Lens Center Green1 X, 376STATE= Lens Center Green1 Y, 240STATE= Lens Center Green2 X, 376STATE= Lens Center Green2 Y, 240STATE= Lens Center Blue X, 376STATE= Lens Center Blue Y, 240STATE= Lens Center Overlay, 0STATE= Lens Sim Sensor, 0STATE= Lens Sim Sensor Rev, 0STATE= Lens Sim Enable Pwq, 0STATE= Lens Sim Enable Poly, 0STATE= Noise Removal, 0STATE= Noise Removal Level, 25STATE= Noise Removal K1, 2000STATE= Noise Removal K2, 1800STATE= Noise Removal K3, 1000STATE= Noise Removal Edges, 1STATE= Noise Removal Kernel, 0STATE= HiDy 14bits, 0STATE= HiDy NR Enable, 0STATE= HiDy PreWB Autogain, 1STATE= HiDy TM Apply S-Curve, 1STATE= HiDy TM Enable LTM, 1STATE= Defect Enable, 0STATE= Defect Max, 1000STATE= Defect Auto Defect Correction, 0STATE= Flash Lamp, 0STATE= Still Global Reset, 0STATE= Global Reset Bulb, 0STATE= Num Capture Frames, 10STATE= Still Mode, 1STATE= Still Capture Average, 0STATE= Still Capture Timeout, 5STATE= Delay before snap, 0STATE= Save 24bpp BMP, 0STATE= Save RAW, 0STATE= Save TXT, 0STATE= Save HEX, 0STATE= Save ITX, 0STATE= Save RAW TIFF, 0STATE= Save 48bpp COLOR TIFF, 1STATE= Save JPEG, 0STATE= Save RAW JPEG, 0STATE= Save BMP Info, 0STATE= JPEG Quality (1-100), 100STATE= Save RAW PNG, 0STATE= Save PNG, 0STATE= Save DNG, 0STATE= Save Selection Rectangle, 0STATE= ICC Profile, 0STATE= Video Screen Capture, 1STATE= RAM Capture, 0STATE= RAM Capture MB, 512STATE= RAM Capture Cycle, 1STATE= WB Xenon Red Gain, 1024STATE= WB Xenon Blue Gain, 1024STATE= WB Led Red Gain, 1024STATE= WB Led Blue Gain, 1024STATE= MAE Overlay, 0STATE= Noise Image Type, 0STATE= Noise Frames, 50STATE= Strip FSP, 1STATE= Thumbnail Overlay, 1STATE= Check Thumbnail Table, 0STATE= CRA Overlay, 0STATE= Allow FAR Access, 1STATE= Pure Raw, 0STATE= AWB Incandescent, 1.3 -0.11 -0.18 -0.47 2.03 -0.49 -0.86 -0.79 5.66STATE= AWB Sun, 2.13 -0.09 -0.15 -0.44 2.09 -0.5 -0.1 -0.31 1.97STATE= AWB Incandescent Gain, 1 1STATE= AWB Sun Gain, 1 1STATE= WB Custom, 1 0 0 0 1 0 0 0 1STATE= WB Custom Xenon, 1 0 0 0 1 0 0 0 1STATE= WB Custom Led, 1 0 0 0 1 0 0 0 1STATE= AWB Weight Map, 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0STATE= Lens Curve Red, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green1, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Green2, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= Lens Curve Blue, C04037602403F800000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000STATE= RGBC Sigma_S, 1STATE= RGBC Sigma_I, 0.005STATE= RGBC Smooth_Th, 0.1STATE= HiDy Matrix, 1.6475 -0.7464 0.0989 -0.0636 1.0086 0.055 -0.0266 -0.8366 1.8632STATE= HiDy NR Noise Model Coef, 1STATE= HiDy PreWB Gb, 1STATE= HiDy PreWB Gr, 1STATE= HiDy TM Peak Percent, 0.003STATE= HiDy TM Sharp S, 2STATE= Gain Table, (null)](http://harvestimaging.com/blog/wp-content/uploads/2015/08/next_blog_41-300x191.jpg)