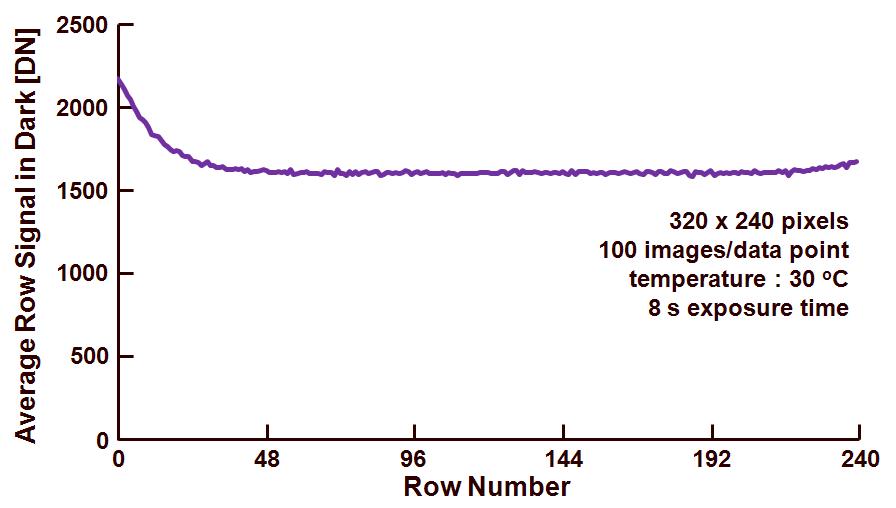

From the measurements of the row FPN and the column FPN, it was learned that the device-under-test (DUT) has a large shading component in dark. (Shading refers to a gradual change of a particular parameter from top to bottom and/or from left to right.) So it will be a very valuable exercise to measure this shading component.

To evaluate the dark shading, the same images are used as before : multiple dark images taken at room temperature and at different integration times. To quantify the dark shading, the images taken at an exposure time of 8 seconds are used : at 8 seconds, the average dark signal is about 25 % of the saturation level. Because dark shading is the low frequency variation of the dark signal, the following procedure is followed :

– all images captured at 8 seconds integration time are averaged, in this way the temporal noise will be reduced,

– the averaged image will be forced through a low-pass filter with a 9×9 filter kernel. This operation will reduce the (high-frequency) FPN.

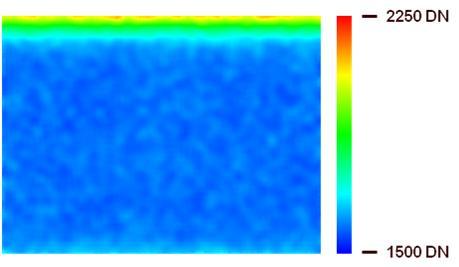

The result after averaging and filtering is shown in figure 1.

Figure 1 : low-frequency variation in dark signal at 8 second integration time.

Clearly visible in figure 1 is the non-uniformity of the dark signal. Its value is slightly increasing towards the lower side of the sensor, but it is strongly increasing towards the top side of the sensor. From left to right the dark signal seems to be more constant. This result is in full agreement with the column FPN and row FPN calculated in an earlier blog. Those results indicated already a large variation in average row value, while the average column value was nearly constant.

The shading illustrated in figure 1 can be expressed as :

– the peak to peak value, equal to 561 DN,

– maximum-minimum value, equal to 2116 DN and 1555 DN respectively.

In principle these numbers are more or less meaningless without any further “reference”. The additional parameters needed are :

– evaluation temperature, being room temperature,

– integration time, being 8 seconds,

– dark signal offset, being 819 DN,

– average dark signal in dark without offset correction, being 1637 DN,

– average dark signal in dark with offset correction, being 818 DN.

Comparing these numbers one can state that the dark signal shading is pretty large compared to the average signal in dark. This can have some very annoying consequences : dark reference lines/columns are always located next to the active pixels. So these references lines and columns can be situated in part of the sensor where the dark signal is deviating quite a bit from the average dark signal and/or the average dark signal in the center part of the sensor. In this way the dark reference signal generated by the signal processing will be too high, and image details in dark might get lost !

In the case of such a large dark shading with possible issues with the dark reference lines, another way of creating a black reference is needed :

– or using black reference columns with the risk of generating row-wise noise,

– or using a black reference frame and perform a dark compensation on pixel level.

Success !

Albert, 23-11-2011.